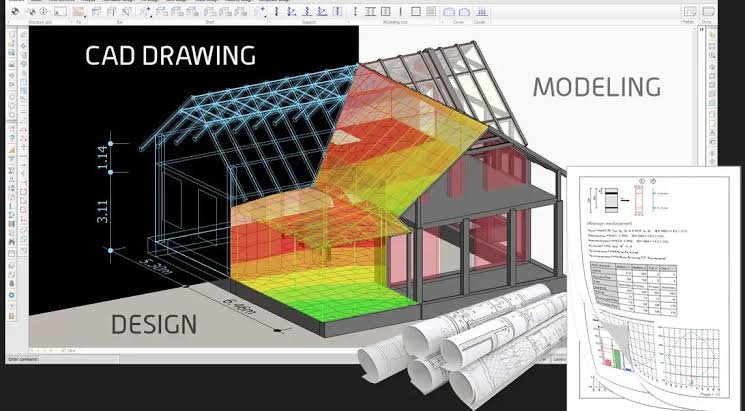

Structural engineering is a very technical field and it is all about coming up with accurate and efficient designs. Contemporary Computer-aided Design (CAD) tools have come as a boon to engineers as all advanced features are equipped with drafting where the engineers can draw the fabrication shop drawings with precision besides estimating the cost of each particular design. These tools not only improve the accuracy of structures’ designs but also optimize the processes, helping to meet project deadlines and costs. Hence, this blog seeks to explain the various tools under CAD that are useful to structural engineers as well as elaborate their uses and the advantages that accompany them.

The Role of CAD in Structural Engineering

CAD tools have risen to be almost compulsory in structural engineering due to the realism they bring while designing structures. They help in making fine drawings that are essential if structures are to be safe and sturdy enough to meet the intended use. CAD integration in design drafting assists engineers in the manipulation of challenging designs with minimal chances of making errors, hence enhancing project results. Also, CAD tools improve the interaction of team members, making it easier to work in a team during the design and construction phases.

Advanced Features for Designing and Drafting

Another major strength found in many of the modern CAD software systems is the sophistication of the available drafting modes. They offer numerous functions that make it easier for engineers to develop quality drawings on the computer. For example, commonly used software for CAD like AutoCAD and Revit-Architect have features of parametric designs meaning that users may specify and change certain design variables with ease. This is especially beneficial to structural engineers who can make modifications to their designs and plans, in striving for an optimal solution without having to redraw a whole project.

Also, CAD tools are surrounded by a rich content database of pre-built components like beams, columns, and joints that may be directly integrated into design projects. Besides, it takes less time, and in doing so, ideas pass through the necessary checks and are adjusted to meet the requirements of the legislation of the country. Another advantage, that has to be mentioned, is the opportunity to create models in three dimensions. The three-dimensional model gives a better view of the structure than the two-dimensional drawing hence facilitating the detection of problem areas by the engineers and hence the decision on changed design.

Enhancing Fabrication Shop Drawing Services

Fabrication Shop Drawings Services refer to detailed plans of fabrication that locate every aspect of a structure in a work setting and indicate how fabrication is going to be done. These drawings are important in as much as they help in making the components with specific dimensions and assist in construction to make sure the components fit well together. Many aspects make CAD tools nice to have when it comes to working on fabrication shop drawings, for example, more precision.

For example, such programs as Tekla Structures, AutoCAD, or SolidWorks contain instruments that allow the creation of detailed 3D models of the structural members. Such models entail dimensions and tolerances that can be linked with the physical parts that are to be constructed. It also makes it easier for engineers to determine clash minus, meaning that one can easily find areas of conflict and clear them before construction. This is good as it will reduce tear and turns as well as time wastage when constructing the building.

Precision for Wood Framing Cost Estimator

Cost control as an element of Wood Framing Cost Estimators is major because of the fact it determines and outlines project costs and timeframes. Hence, the cost estimators for wood framing depend on the accurate and detailed design to formulate the cost estimates. CAD tools are accurate thus offering details that are useful in coming up with a viable and realistic plan for the cost estimation.

AutoCAD and SketchUp are some of the CAD programs that enable the engineer to use them in preparing technical plans and models of wooden frame structures. These drawings consist of dimensions and tolerances that help in estimating the amount of material to be used. It is thus possible to use CAD tools to incorporate material databases including the current cost of the particular material required to arrive at the real cost of the job.

Improving Collaboration and Communication

Since the CAD tools enable real-time sharing of documents and design data with different stakeholders who may be involved in the project, effective communication is enhanced. Today’s CAD tools have options for cloud and this facilitates sharing of work on the same project across different people and/or regions. This helps in the coordination of activities by providing a common ground to all the stakeholders so that everyone is on the same page.

For instance, Autodesk has BIM 360 and Trimble connect which are cloud-based tools allowing architects, engineering, and construction teams to share work on projects. These include communication channels where people can share designs, give and take feedback on designs, and schedule online meetings among others. CAD tools help to enhance the recovery of challenged human practices by offering a single-point central platform which workers can work from, thereby lowering the rate of errors and miscommunication.

Streamlining Project Workflows

Computer-aided design tools are therefore beneficial in the organization of workflows in the construction industry right from design to the construction phase. Most of these tools transport a number of the processes related to structural engineering, therefore assisting the engineers to work more effectively. For instance, instead of taking several hours to draw(layout) designs and models, CAD tools do it in a shorter duration. This release of tedious tasks enables engineers to work on other tasks that involve their expertise and skills.

Also, on the graphical interface of CAD tools, one can find the possibilities to automate some work that is time-consuming, for instance, making a list of the materials and calculating quantities. I have realized that this format also saves a lot of time as well as minimizing mistakes so that designs are profoundly correct. Interconnecting CAD solutions with other project-related tools even increases the organizational advantage, as engineers can control all the processes from a single interface.

Conclusion

The existence of CAD in the structural engineering profession has introduced new capabilities for designing drafting, fabrication, shop drawing, and cost estimation. These tools improve the design’s precision and productivity, optimize the sequences and processes, and enable the sharing of information among project actors. Through the application of modern CAD software, structural engineers can adequately design their projects for safety and efficacy enhancing their delivery of projects. When it comes to drafting, fabrication, or shop drawing services, or perhaps for wood framing cost estimation, the CAD tool you use has a considerable influence on your work.